Product use:

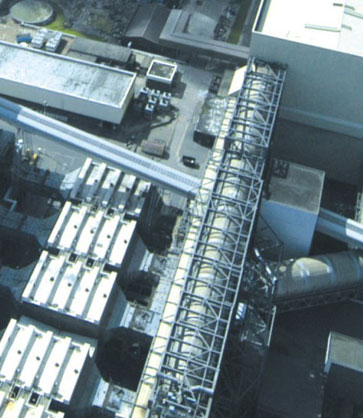

Suitable for oil, natural gas, chemical industry storage tanks, pipelines, open-air large equipment and other sunshine surface

According to the national standard GB11174-89, liquefied petroleum gas tanks, light oil tanks, chemical light low-boiling point material storage tanks, the environmental surface temperature in summer does not exceed 50℃. The northeast does not exceed 45℃. In order to reduce the surface temperature of the iron sheet, the usual method is to use spray water cooling, but the effect is not satisfactory and waste water and electricity resources, pollution of the environment, corrosion of the iron sheet, choose to use building reflection insulation and waterproof coating is the best solution to solve the problems caused by the sun.

Product features:

Different from the traditional thermal insulation materials, the building reflection thermal insulation waterproof coating can refuse more than 90% of the solar radiation heat to the outer surface of the iron sheet building, and fundamentally remove the solar heat causing factors, which is the most ideal cooling and insulation scheme for chemical storage tank buildings in the strong sunshine season.

Create a economical and safe iron inner environment

The high temperature caused by sunshine causes the atmospheric pressure inside the sealed iron sheet to rise sharply, and the relative safety factor is also greatly reduced, while the long-term high pressure state also has a certain impact on the life of the iron sheet, if the gas is discharged and decompressed, the light material oil tank produces breathing, and the volatilization of oil and gas or chemical substances causes resource waste and environmental pollution. The use of building reflection heat insulation and waterproof coating to remove high temperature harassment is of great significance from the perspective of economy and safety.

Incredibly low cost

Compared with other thermal insulation schemes, the building reflection thermal insulation waterproof coating materials and construction costs are very low.

Potentially huge energy savings payback

If the spray device is used to resist the high temperature caused by the sunshine of the iron sheet, the cumulative electricity and water consumption is often not a small number, and this cost is completely eliminated after painting the building reflection thermal insulation and waterproof paint on the tank surface.

Environmental protection and pollution-free, use confidence is guaranteed

Building reflection insulation and waterproof coating is an environmentally friendly water-based coating, which has been tested by the National Chemical Building Materials Testing Center and meets the standard requirements. The product is non-toxic, tasteless, odorless, non-radioactive and non-heavy metal components.

Protect the metal layer of the iron sheet and extend the service life of the iron sheet

Building reflective thermal insulation waterproof coating has good waterproof effect, after coating the outer surface of the iron sheet, it can effectively slow the metal oxidation rust process and extend the service life.

Building reflective insulation and waterproof coating is specially developed for chemical plants, oil refineries, oil depots, oil stations. Can also be used to heat the surface of the pipeline pearl tile, waterproof, thermal insulation performance is excellent, temperature resistance of up to 150℃, high temperature in summer, can prevent the surface of the oil tank due to the heat caused by the temperature rise, the cooling range can be up to 8-30℃, so greatly reduce the gasoline, diesel, kerosene, chemical oil and other light oil evaporation, and can effectively waterproof to prevent the oil tank oxidation rust, It can extend the life of the oil tank for 5-10 years. After painting the oil tank, the coating is valid for 5 years.

Technical indicators:

1. State: gelatinous liquid

2. Whiteness: 85

3. Coating appearance: white and smooth

4. Thermal reflectance: ≥90%

5. Solid score: ≥50%

6. Heat insulation: 0-50℃

7. Water resistance: 100%, no bubbling (test after 72 hours of construction)

8. Corrosiveness: None

9. Film hardness: 2H

10. Washability: ≥500 times

11. Coating rate: 3-4 square meters/kg

Construction requirements:

one Brush coating, roll coating, spraying can be

2. Remove the dust on the target surface before construction

3. It is recommended to dilute with 10% water and stir well before construction

4. The first and second roads should be constructed four hours apart

5. The construction environment temperature is above 10℃, and the relative humidity is below 85%.

Note: This product has no professional anti-rust function, if the metal material has more serious rust, it is recommended to do special anti-rust treatment, and then refer to the normal construction method of the product.

Special note:

one The substrate should be smooth and clean. If the surface is too dry, spray water to wet it before construction

2. It must be mixed well before construction

3. The paint is valid for 2 years, long-term placement of the paint will appear stratified, and the construction will not affect the quality after mixing

4. No rain is allowed within 3 hours after construction

5. After construction, the tools should be washed and dried in time when they are not dry, otherwise they will condense and be scrapped

6. This product is non-toxic, if accidentally splashed into the eyes, should immediately rinse with water.

Service telephone

Service telephone